Background

The magnetic fields of planets and stars are thought arise from a sort of continuous electrical generator driven by the turbulent flow of an electrically conducting fluid. This "dynamo effect," proposed in 1919 by Larmor, is widely accepted as a likely explanation for the dynamic, strong, and long lasting magnetic fields of astrophysical objects. However, the wide range of time and length scales relevant to turbulent flows at realistic geophysical and astrophysical parameters prohibits direct numerical simulation, and makes any computational study difficult and time intensive. Laboratory experiments can provide a great deal of data in parameter space beyond that reached in practical theoretical studies and that occupied by planets and stars. Experiments remain a useful tool for developing an understanding of the rich variety of phenomena that arise in turbulent flows of magnetized fluids.

Goals

- Create a homogeneous, Earth-like dynamo in the lab.

- Demonstrate a self-generating magnetic field in an unconstrained flow.

- Characterize the nature of the transition to dynamo action.

- Explore the mechanism which causes Earth's magnetic field to saturate.

- Understand the dynamics of the saturated field, with particular interest in pole reversals.

Our experiments

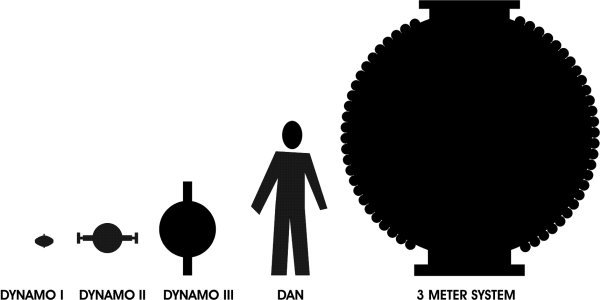

Dynamo I

Dynamo I

Our first rotating convection sodium experiment (20 cm diameter).

Dynamo II

Dynamo II

A mechanically driven sodium device (30 cm diameter).

Dynamo III (60 cm)

Dynamo III (60 cm)

Our second rotating convection sodium experiment (60 cm diameter).

Dynamo 3.5 (60 cm)

Dynamo 3.5 (60 cm)

A modification to Dynamo III to allow mechanical drive of an inner shaft (instead of convection) in addition to rotation of the outer vessel.

Bigger is better when it comes to dynamo experiments. The larger the experiment, the larger the magnetic Reynolds number. The larger the magnetic Reynolds number, the better your chances are to self-generate magnetic fields.

Safety

These experiments use liquid sodium as the test fluid because of its high electrical conductivity. Sodium is chemically volatile, however, and using it safely requires caution, training, and specialized procedures. Oversight of our safety plan comes from two routes: the University of Maryland Environmental Health and Safety office, and the Engineering and Safety team at DuPont Sodium production facility. All of our safety plans and many refinements of those plans have been reviewed, and will be re-reviewed by these teams. Those recommendations will be strictly followed. Included in those plans are building modifications, personal protection equipment, and training. DuPont Corp. has given a day of training for both research personnel and the local fire department personnel on the safe handling and fire extinguishing practices for sodium. One pallet of drums of the soda ash fire fighting material will be on hand prior to receipt of the material. The safe conduct of our existing sodium experiments is some evidence of our ability to conduct these experiments, although the increased volume will require increased vigilance.

- D. An, P.B. Sunderland and D.P. Lathrop. Suppression of sodium fires with liquid nitrogen. Fire Safety Journal. 58: 204-207 (2013). [DOI]

Dissertations

- Matthew Adams, Magnetic and acoustic investigations of turbulent spherical flow, UMD 2016

- Santiago A. Triana, Inertial waves in a laboratory model of the Earth's core, UMD 2010

-

Daniel S. Zimmerman, Turbulent shear flow in a rapidly rotating spherical annulus, UMD 2010

Corrected Torque Transducer Schematic: replaces p. 310 - Matthew S. Paoletti, Experimental characterization of turbulent superfluid helium, UMD 2010

- Douglas H. Kelley, Rotating, Hydromagnetic laboratory experiment modelling planetary cores, UMD 2009

- Woodrow Shew, Liquid sodium model of earth's outer core, UMD 2004

- Daniel R. Sisan, Hydromagnetic turbulent instability in liquid sodium experiments, UMD 2004

Publications

- S.A. Triana, D.S. Zimmerman, H.-C. Nataf, A. Thorette, V. Lekic and D.P. Lathrop. Helioseismology in a bottle: modal acoustic velocimetry. New Journal of Physics. 16 (11): 113005 (2014). [DOI] [ADS] [arXiv]

- D.S. Zimmerman, S.A. Triana, H.-C. Nataf and D.P. Lathrop. A turbulent, high magnetic Reynolds number experimental model of Earth's core. Journal of Geophysical Research (Solid Earth). 119: 4538-4557 (2014). [DOI] [ADS]

- M. Rieutord, S.A. Triana, D.S. Zimmerman and D.P. Lathrop. Excitation of inertial modes in an experimental spherical Couette flow. Physical Review E. 86 (2) (2012). [DOI] [ADS] [arXiv]

- S.A. Triana, D.S. Zimmerman and D.P. Lathrop. Precessional states in a laboratory model of the Earth's core. Journal of Geophysical Research. 117 (B4) (2012). [DOI] [ADS]

- D.P. Lathrop and C.B. Forest. Magnetic dynamos in the lab. Physics Today. 64 (7): 40 (2011). [DOI]

- H. Matsui, M. Adams, D. Kelley, S.A. Triana, D. Zimmerman, B.A. Buffett and D.P. Lathrop. Numerical and experimental investigation of shear-driven inertial oscillations in an Earth-like geometry. Physics of the Earth and Planetary Interiors. 188 (3-4): 194-202 (2011). [DOI] [ADS]

- D.S. Zimmerman, S.A. Triana and D.P. Lathrop. Bi-stability in turbulent, rotating spherical Couette flow. Physics of Fluids. 23 (6): 065104 (2011). [DOI] [ADS] [arXiv]

- D.H. Kelley, S.A. Triana, D.S. Zimmerman and D.P. Lathrop. Selection of inertial modes in spherical Couette flow. Physical Review E. 81 (2) (2010). [PDF] [DOI] [ADS]

- S.A. Triana, D.H. Kelley, D. Zimmerman, D. Sisan and D.P. Lathrop. Hopf bifurcations with fluctuating gain. Astronomische Nachrichten. 329 (7): 701-705 (2008). [PDF] [DOI] [ADS]

- D.H. Kelley, S.A. Triana, D.S. Zimmerman, A. Tilgner and D.P. Lathrop. Inertial waves driven by differential rotation in a planetary geometry. Geophysical & Astrophysical Fluid Dynamics. 101 (5-6): 469-487 (2007). [PDF] [DOI]

- D.H. Kelley, S.A. Triana, D.S. Zimmerman, B. Brawn, D.P. Lathrop and D.H. Martin. Driven inertial waves in spherical Couette flow. Chaos. 16 (4): 041105 (2006). [DOI] [ADS]

- H.H. Kolm, F. Winterberg and D. Lathrop. Early Geodynamo Work. Physics Today. 59 (10): 14 (2006). [DOI] [ADS]

- W.L. Shew and D.P. Lathrop. Liquid sodium model of geophysical core convection. Physics of the Earth and Planetary Interiors. 153 (1-3): 136-149 (2005). [DOI] [ADS]

- B.E. Brawn, K. Joshi, D.P. Lathrop, N. Mujica and D.R. Sisan. Visualizing the invisible: Ultrasound velocimetry in liquid sodium. Chaos. 15 (4): 041104 (2005). [DOI] [ADS]

- S. Fauve and D. Lathrop. The Fluid Mechanics of Astrophysics and Geophysics. [DOI]

- D. Sisan, N. Mujica, W. Tillotson, Y-M. Huang, W. Dorland, A. Hassam, T. Antonsen and D. Lathrop. Experimental Observation and Characterization of the Magnetorotational Instability. Physical Review Letters. 93 (11) (2004). [DOI] [ADS] [arXiv]

- D.R Sisan, W.L Shew and D.P Lathrop. Lorentz force effects in magneto-turbulence. Physics of the Earth and Planetary Interiors. 135 (2-3): 137-159 (2003). [PDF] [DOI] [ADS]

- W.L. Shew, D.R. Sisan and D.P. Lathrop. Mechanically forced and thermally driven flows in liquid sodium. Magnetohydrodynamics. 38: 121-127 (2002). [ADS] [URL]

- D.P Lathrop, W.L Shew and D.R Sisan. Laboratory experiments on the transition to MHD dynamos. Plasma Physics and Controlled Fusion. 43 (12A): A151-A160 (2001). [DOI] [ADS]

- D. Sweet, E. Ott, J. Finn, T. Antonsen and D. Lathrop. Blowout bifurcations and the onset of magnetic activity in turbulent dynamos. Physical Review E. 63 (6) (2001). [PDF] [DOI] [ADS]

- D. Sweet, E. Ott, T.M. Antonsen, D.P. Lathrop and J.M. Finn. Blowout bifurcations and the onset of magnetic dynamo action. Physics of Plasmas. 8 (5): 1944 (2001). [PDF] [DOI] [ADS]

- W.L. Shew, D.R. Sisan and D.P. Lathrop. Dynamo and Dynamics, a Mathematical Challenge. [URL]

- N. Peffley, A. Cawthorne and D. Lathrop. Toward a self-generating magnetic dynamo: The role of turbulence. Physical Review E. 61 (5): 5287-5294 (2000). [PDF] [DOI] [ADS]

- N.L. Peffley, A.G. Goumilevski, A.B. Cawthrone and D.P. Lathrop. Characterization of experimental dynamos. Geophysical Journal International. 142 (1): 52-58 (2000). [PDF] [DOI] [ADS]

- A.B. Hassam, J.F. Drake, D. Goel and D.P. Lathrop. Liquid metal flow encasing a magnetic cavity. Physics of Plasmas. 7 (4): 1081 (2000). [PDF] [DOI] [ADS]

3 meter system

3 meter system